Electronics manufacturing

from prototype to small series production

Everything from a single source: Our certified and flexible electronics production turns your design into a high-quality product.

Electronics manufacturing

For your specific requirements we develop, manufacture, and qualify customized electronic assembly groups as well as ready-made test systems and offer embedded systems the corresponding software.

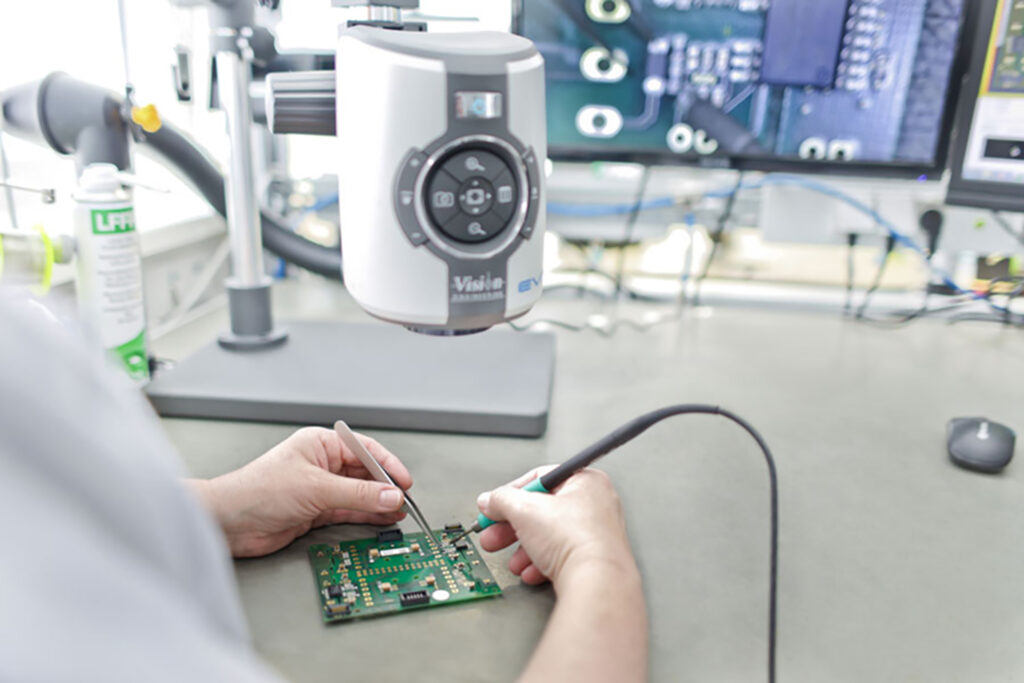

Whether it is about procurement of components, mounting of boards and assemblies, or testing the quality of a finished product and packing it – we are happy to take over the manufacturing of your electronic assemblies as well as power electronics from prototype to small series.

Using the latest process standards such as vapor phase soldering, serial numbers and traceability, we manufacture flex, rigid-flex and multi-layer boards up to 340 x 280 mm (larger possible after arrangement). Provide us with the material or let us take care of procurement using certified suppliers – it is your choice.

Component testing

Every PCB that we produce is checked visually in accordance with IPC-A-610-E. Of course we can also conduct tests in accordance with your customer’s specifications.

CONTACT

We are happy to advise you on your orders and processes, if necessary, even rush orders. Please note that only lead-free materials are used in our production and that our work is RoHS-compliant.